INSTITUTUL NATIONAL DE CERCETARE-DEZVOLTARE PENTRU FIZICA LASERILOR, PLASMEI SI RADIATIEI

Str. Atomistilor 409, 077125 Magurele, Ilfov, Romania

Proiect

Direct laser writing of polymer - graphene composites

<POLYGRAPH>

Summary

Graphene-based polymer nanocomposites (GBPNC) share common features with regard to fabrication methodologies, processing, morphology characterization and fundamental physics. The key to prepare advanced GBPNC is to control the engineering of the polymer-graphene interface. Graphene have a pronounced tendency to agglomerate, making them very hard to disperse homogenously in polymers, regardless of the production process of the polymer nanocomposites. The prevention of aggregation is essential because most of their unique properties are present just in the pristine form. Because of this, a series of surface modifications of graphene are performed in order to make them suitable for homogenous dispersion in polymers. In this respect, oxidation followed by chemical functionalization will facilitate dispersion and stabilization, thus preventing agglomeration. In general, graphene are functionalized by attaching small molecules or polymers chains to the graphene surface. The chemical functionalization of the graphene surface is considered to be an attractive solution because this approach renders them hydrophilic (instead of hydrophobic). An improvement in its solubility results in better dispersion and processability, enhancing the interaction between the filler and matrix to the interface. The general objective of the project is to produce 2D and 3D structures of graphene based polymer nanocomposites with improved electrical, thermal, optical and mechanical properties by direct laser writing of monomer/graphene composite using a femtosecond IR laser. A technology will be developed based on the monomer/graphene material interaction during the laser action. The monomer will be urethane mono(dimethacrylates) in different combinations with graphene and surface modified graphene. The project bring at least two novelties: The polimer matrix is new in the filed of GBPNC and DLW is a new technological approch to incorporate graphene in a polymer matrix starting from monomers.

Project objectives

The general objective of the project is to produce 2D and 3D structures of graphene based polymer nanocomposites by direct laser writing of monomer/graphene composite using a fs IR laser. A technology will be developed based on the monomer/graphene material interaction befor and during the laser action. From the general objective we can identify few secondary objectives related with monomer/graphee mixing protocol and the properties of the written structures with the aim to increase the solubility and omogeneity of graphene in the monomer solution to maximize electrical, thermal and mechanical properties. The properties of the graphene based nanocomposite structures will be correlated with the laser processing conditions.

Experimental

Direct Laser Writing principle

The technique consists in a few steps:

1. Solution preparation: the monomer to be polymerized is homogeneously mixed with a photoinitiator and dissolved in a proper solvent.

2. Solution mounting on the substrate: the working gel described above is poured on a substrate in a thin and uniform layer. A standard method is spin-coating. A simple drop cast can be also used.

3. Laser irradiation: the focused laser beam is moved in the sample volume on the desired path and the polymerization occurs just on the followed trajectory. The focusing element is a microscope objective if the designed structures are nanometric or a lens for micrometric structures.

4. Developing: after irradiation the substrate is washed with alcohol and de ionized water, the none irradiated (monomers) material being removed.

In this way, at the end of the irradiation procedure, on the substrate the only remaining material is the structure we have designed.

Originality

The ideea of producing polymers with controlled size and shape at micro

scale greatly influence various field of physics, chemistry, biology and

medicine. From photonic structures to reconstructive medicine IR

multiphoton polymerization prouved to be a reliable technique.

Because of their good conductivity, thermal stability, and excellent

mechanical strength, graphene and its derivatives are important filler

materials for polymer composites. The properties and performances of

graphene based polymer composites not only depend on the quality of

graphene filler and polymer matrix, but also depend on the dispersity of

the filler, the bonding between the filler and matrix, and the ratio of

filler to matrix. These factors are mainly determined by the fabrication

processes.

The interaction with the laser starts within the photoinitiator and then the monomers, laser doesn’t interact with graphene, it will preserve the functionalities, radical-type polymerization increase the solubility of graphene materials and no other aditional preparation should be made.

These aproach opens the way to fabricate conductive, transparent, mecanically resistant electronics for the flexible electonics industry.

The project bring at least two novelties in the field of graphene based polymer nanocomposite materials. First, from the point of view of the matrix, urethane mono(dimethacrylates) is a new matix for the graphene based polymer nanocomposite. Second, the DLW is a new technological approch to incorporate graphene in a polymer matrix starting from monomers.

Expected results

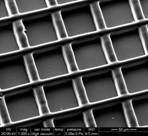

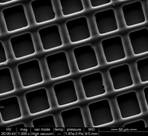

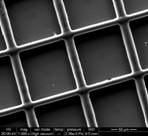

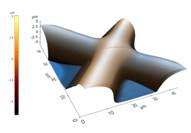

Photopolimerization technique will allow us to fabricate 2D and 3D structures of graphene based polymer composites to be used in fotonics and optoelectronics. In the next images we show some of the possible 2D and 3D structures.

30x30 lines polymerized (N,N’-(methacryloyloxyethyl triehtoxy silyl propylcarbamoyloxyhexyl)-ureea) sample

An experimental laboratory model (technology) for preparation of the graphene based polymer nanocoposite materials based on the DLW technique will be developed.

Phase list

|

Phase no. |

Phase title |

Involved partners |

Start month (1 ... n-1) |

End month (2 ... n) |

|

1 |

Preparatory phase |

CO, P1,P2,P4 |

1 |

8 |

|

2 |

Photo-polymerization of monomer - graphene systems |

CO, P1,P2,P3 |

9 |

20 |

|

3 |

Photo-polymerization of monomer - functionalized graphene systems |

CO, P1,P2,P3 |

21 |

32 |

|

4 |

3-D direct writing and polymerization of monomer - graphene systems |

CO, P1,P2 |

33 |

36 |

|

Available research infrastructure |

|

Two ultrafast laser systems (GIWALAS - 200 fs, 2 kHz, 775 nm, max. 0.6 mJ; TEWALAS - CPA amplifier at 30 fs, 10 Hz, max. 450 mJ, oscillator at 10 fs, 80 MHz, 800nm); one workstations for Direct Laser Writing (DLW) equipped with high accuracy positioning stages (steppers 50x50x50 mm3, piezo 300x300x300 mm3; equipments for laser beam characterisation (CCD spatial beam profilers, autocorrelators for temporal profile measurements, spectrometers, energimeters); optical tables, precised optical mounts and stages, optical components for UV-VIS-NIR; CCD cameras for visualization and focalization of the samples equipments, Scanning Electron Microscope (SEM), Atomic Force Microscope (AFM), Spectro-ellipsometer, Fourier Transform Infrared Spectroscope (FTIR), X-ray Diffractometer (XRD), Secondary Ions Mass Spectroscopy (SIMS), Dielectric spectroscopy bridge, are available at INFLPR (CO). P1 has an available research infrastructure to assure all conditions achieving the objectives stipulated in the present project. Some of them are mentioned below: Bruker Avance DRX-400 NMR Spectrometer; Bruker VERTEX 70/70v FT-IR Spectrometer; UV-VIS SPECORD 200 Analytik Jena Spectrophotometer; PerkinElmer 2400 Series II CHNS Elemental Analyzer; Microwave Reaction System DISCOVER (CEM 500); Scanning Electron Microscope QUANTA 200 with elemental analysis system EDAX; Goniometer Optical Video Contact Angle System KSV; Temperature differential scanning calorimeter Pyris Diamond DSC; Perkin Elmer; Shimadzu AGS-J testing machine (1kN). P2 has an available research infrastructure to assure all conditions achieving the objectives stipulated in the present project. Some of them are mentioned below: Zwick T1-FR005TN Universal Mechanical testing machine; Universal machine for static mechanical testing of materials LFM 30Kn; Microdurimeter FM 700; UV-Vis 570 Jasco spectrophotometer equipped with integrating sphere; UV-Vis Lambda 35 PerkinElmer Spectrometer; Tunneling electron microscope STM-Ntegra; Type confocal optical microscope NIKON system, Dilatometer L75 PT, DSC 204 F1 Phoenix differential calorimeter, dynamic mechanical analyzer DMA Q8 apparatus techniques coupled thermal analysis (TG-DTA-DSC-FTIR) STA 409PC, analysis STA 449 F3 Jupiter thermal, physical property measurement system - Quantum Design PPMS apparatus LUMIPOL type 3. P3 Available infrastructure, necessary in the project (http://www.infim.ro Facilities and services section): Analytical Atomic Resolution Electron Microscope JEM-ARM200F (JEOL) with field emission gun (FEG) operating at maximum 200 kV in the high resolution transmission/scanning microscopy (HRTEM/ HRSTEM) modes. JEOL 200 CX electron microscope for conventional TEM, diffraction contrast imaging, electron diffraction; TEM specimen preparation room provided with several thinning techniques; FT Raman Spectrophotometer RFS 100/S (Bruker ). |

|

Budget breakdown / destination (lei) |

||||||||

|

|

Personnel costs |

Logistics |

Travel |

Indirect costs |

Total |

|||

|

Equipments |

Materials |

Subcontracting |

||||||

|

Coordinator (CO) |

Public Budget |

530167 |

5000 |

28000 |

0 |

21000 |

115833 |

700000 |

|

Partner 1 |

Public Budget |

160000 |

50000 |

95000 |

0 |

25000 |

70000 |

400000 |

|

Partner 2 |

Public Budget |

317000 |

35000 |

40000 |

0 |

15000 |

93000 |

500000 |

|

Partner 3 |

Public Budget |

306000 |

0 |

6000 |

0 |

8000 |

80000 |

400000 |

|

Total |

1313167 |

90000 |

169000 |

0 |

69000 |

358833 |

2000000 |

|

Expected impact

|

Main impact of this projects is the opening of new research directions and applications for the most attractive material of the moment. Target indicators are: -An innovative product – with a degree of innovation appreciated as superior; -A new technology - with a performance level assessed as high; -Recipes and reinforcement solutions - with a degree of novelty appreciated as high. Economic impact is related with the transfer of knowledge to the industry in Romania but also at international level. New material with electrical, optical, mechanical and thermal properties for known (optoelectronics, photonics, flexible electronic industry) and yet unknown applications. Industrial technological lines can be imagine for large scale production. Scientific impact is related with the interdisciplinarity of the project activities and the common use of knowledge in a new emerging field. A new technology (laboratory model) will be developed for graphene based polymer composites. Interdisciplinarity of the project will allow the interaction with other scientific comunities. Social impact: young scientists are already involved in the research activity. Consortium groups have 18 Potdoc, PhD Students or Master Students. The project will allow them to benefit of consortium equipment and knowledge and to face new and advanced methods for materials synthesis, processing and characterization. The project will create opportunities for education at specialization/master/PhD students to prepare diploma, master and PhD thesis. 3.2. Dissemination and/or exploitation of project results, and management of intellectual property rights The scientific production will be identified as the results of this joint research project. It will be encouraged to publish in high impact factor journals. The communications at international conferences will be oral presentations eventually doubled by posters that will identify other aditional aspects of the research. Ethical issues and intelectual property rights In order to fulfill the ethical conditions during the project development will be applied the requirements established by the Law206/27.05.2004 regarding the good practice in research, development and innovation activity, and the requirement of the European laws. The allocation of the intellectual property rights among the participants will be discussed in the Management Comity. The already existing know-how will be established and the ownership of the new know-how will be discussed. The rights on the patents resulted from the research will belong to all partners, at percentages in accord with the actual laws. The Management Comity will decide regarding the result dissemination. The project does not involve problems regarding bioethics and biosecurity (human or animal subjects, forbidden chemicals, poisons, explosives are not used). |

2012 © George Epurescu