NATO - Science for Peace

SfP 982671

* Background and Justification

Responding rapidly to a chemical or biological terrorist attack requires the ability to monitor and detect what chemical or biological agents may be present. Four phases are identified in such a case: Notification, First- Responder, Characterization, and Restoration (decontamination and remediation). During the initial notification phase, an operations center identifies an event on the basis of sensors, intelligence information, or data on casualties.

The demand for rapid prototyping technologies that can effectively be used for developing next generation chemical sensors for the detection of air-borne species has increased rapidly, in particular, since the attack on the World Trade Center on September 11, 2002. In “Advances in Sensing with Security Applications”, (Proceedings in Advanced Study Institute, Il Ciocco, Italy, 2005, Edited by Jim Byrnes”) is the authors note that “the sensor must be able to find the proverbial “needle in the haystack”. The sensors need to be, “multifunctional, robust, low cost, accurate, reliable, would provide definitive information to the decision factors”. It is then a continuous and increasing need of new solutions, active membranes, and simple detection systems.

The present project aims at the development of novel fabrication methods for the deposition of patterned single or multilayer thin-film architectures based on mild, “solvent-free” or “dry” material transfer techniques. The new techniques which fulfill these requirements are: Matrix Assisted Pulsed Laser Evaporation – Direct Writing (MAPLE-DW) and Laser Induced Forward Transfer (LIFT). These methods are have been demonstrated to be extremely versatile in the deposition of polymer thin films with a lateral resolution in the micron scale (“pixels”). The technique can also be used to deposited multi-layers of polymers which can not be done using solvent based-methods. These pixels will be the active layers in new developed SAW and BAW-TFBAR electro-acoustic devices.

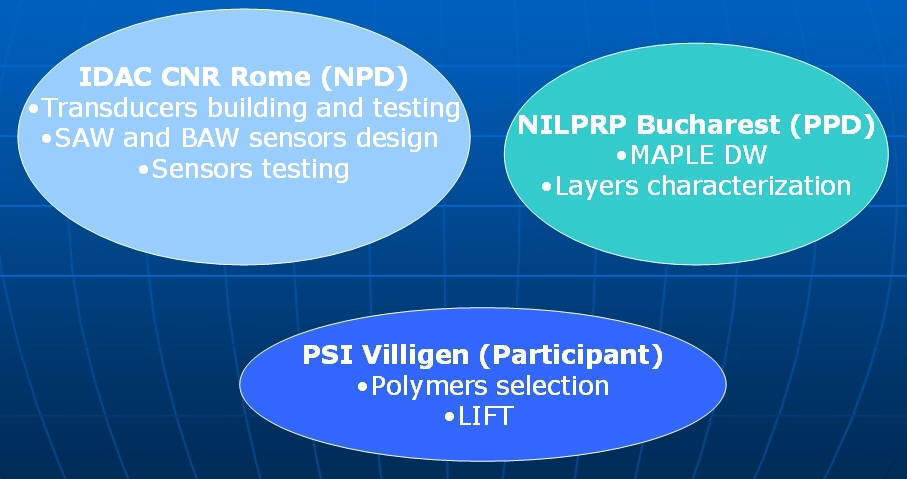

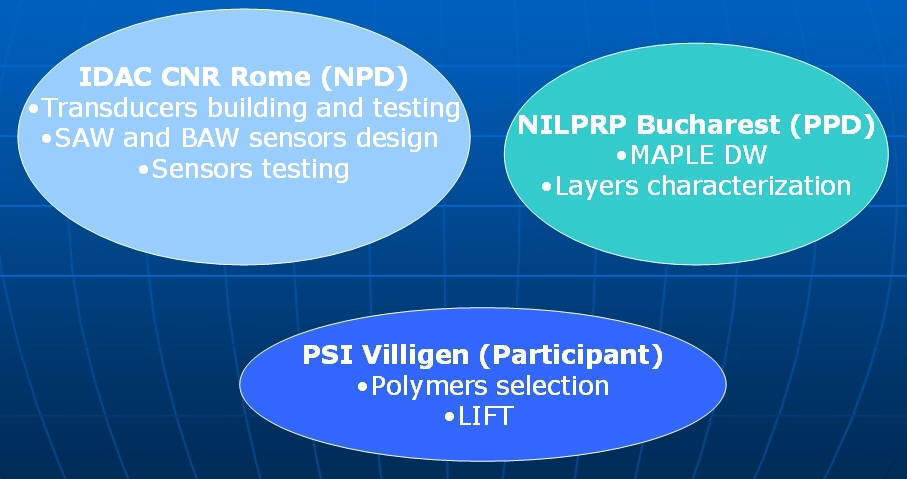

* Participants

The three groups involved in the project have complementary experience and equipments for warfare agent sensor realization.

The group from IDAC Rome (Italy), head by Dr. Enrico Verona, has an outstanding reputation in the field of acoustic sensors. They are or were involved in international and national projects based on this experience; some of these projects are directly connected with the topic of the present NATO SfP project (EUCLID project “Miniaturized Chemical Warfare Agents Vapour Detector” (2001-2004). The main technological equipments existing at the Institute in Rome consist of deposition systems (sputtering and thermal evaporators) for metal electrodes, piezoelectric layers, etc.; mask aligners, Reactive Ions Etching system, laser mask writer, wafer dicing, etc. All these equipments are located in “clean room” laboratories (different class: from 100 to10,000). Moreover, facilities are available for testing thin film layers and microstructures, for testing SAW and BAW devices (Network Analyzers, electronics laboratory, optical laboratory), for testing sensors (gas flow meters/controllers), for modeling electro-acoustic devices and SAW propagation (PC facilities, simulation programs, design and construction of electronic conditioning circuitry. They are able to develop a complex and complete technology for sensors fabrication.

NILPRP Magurele (Romania) has already basic infrastructure and equipments for deposition and characterization of thin films: laser working at four wavelengths (1064 nm, 532 nm, 355 nm, 266 nm), repetition rate 1-10 Hz, thin films deposition: i) pulsed laser deposition chambers with multi-target system and substrate heater; ii) radiofrequency assisted Pulsed Laser Deposition systems; iii) Matrix Assisted Pulsed Laser Evaporation system, and analysis: i) Atomic Force Microscope; ii) Dielectric Impedance Analyzer; iii) X-ray diffractometter; iv) Spectroellipsometry.

PSI Zurich (Switzerland) has complementary deposition equipment and characterization, such as lasers: i) ArF/KrF excimer (λ=193 nm and 248 nm); ii) XeCl excimer laser (λ=308 nm); iii) Nd:YAG laser (λ=1064 nm, 532 nm, 355 nm, 266 nm); v) Kr+ laser (CW), multi line; iv) CO2 laser, tunable, CW or pulsed (40 W) and several UV and VUV lamps; Reactive Ion Etching; Thin Film Deposition: i) LIFT chamber with x,y,z computer controlled stages; ii) MO-CVD (under construction) iii) pulsed laser deposition chambers with various in-situ analytical techniques. Sample preparation: Spin coater with dispenser, draw blade applicator for film drawing, ball milling and high speed mixing. Analysis: i) profilometry; ii) Scanning electron and standard optical microscopies; iii) Raman-microscopy; DRIFT-IR spectrometer; iv) Quartz micro balances for measurement of ablation or deposition rates.

* Objectives

The overall goal of this project is to realize new sensors array for chemical warfare agent detection with new materials and using a new technique to make the sensor. To reach this goal several objectives should be followed: 1) identification of the most sensitive chemoselective polymer for warfare gas detection (nerve agents – G and V series - and mustard gases); 2) construction of SAW and /or BAW sensors with appropriate design for polymers “pixels” writing by MAPLE DW and LIFT; 3) testing of multi-membrane sensors array fabricated using MAPLE DW and LIFT and 4) sensors testing with both simulants and real warfare gases.

* Implementation of Results

The main scientific results obtained during the project will be presented to the National Conference in Physics organized each ear in Romania and to the Conference of Physics of University of Bucharest organized each year in Magurele Campus, where both Faculty of Physics from University of Bucharest and NILPRP are located. Dr. Maria Dinescu is associate professor to Faculty of Physics of Craiova University: Craiova is a town situated at 300 km from Bucharest. During her teaching activity the main results obtained in MAPLE DW and LIFT polymers processing and pulsed laser deposition of piezoelectric layers will be inserted as laser based techniques for material processing.

Partial achievements will be presented as communications to the most important conferences devoted to Materials Research, Laser Processing, Chemical sensors, Security: European Material Research Society Conference (E-MRS), Material Research Society Conference (MRS), International Conference on Laser Ablation ( COLA), IEEE Ultrasonic Symposium. The most significant scientific results will be send for publication in ISI International Journals.

* Pixel transfer of SAW devices - preliminary results

Three types of surface acoustic waves (SAWs) devices have been coated in order to optimize the deposition technique: delay lines, 2-ports resonators and 1-port resonators.

With respect to SAW devices the research has been oriented to the use of propagations materials showing higher acoustic-wave velocities, such as silicon, sapphire and diamond, exploiting piezoelectric films of AlN (which is the piezoelectric material showing the higher sound velocity). This has allowed a higher frequency of operation of the SAW devices (at a given line-width resolution of the interdigital transducers) which, in turn, can give rise to higher SAW sensor sensitivity. To this purpose it is possible to take advantage from the exploitation of pseudo-SAW modes, which we are presently investigating for the AlN/diamond structures, where the acoustic velocity can reach values as high as 18.000 m/s.

SAW devices on AlN/diamond/Si structures:

Delay line (a) and 2 port resonator (b).

In particular, besides the coating thickness that, as it is well known, affects the phase SAW velocity and the insertion losses, it’s critical to obtain a high homogeneity of the coating in order to minimize scattering and diffraction of SAWs. For this, the main parameters (fluence, distance for transfer, thickness, homogeneity and area of the film coating) were controlled so well defined and uniform polymer pixels were obtained.

Optical images of polymer pixels deposited on various SAW devices are shown above for: a) one PEI polymer pixel transfer with Nd:YAG; b) one PEI polymer pixel transfer with XeCl excimer laser; c) one PEI polymer pixel transfer with Ti:Saphire; d) crop area from the one PEI polymer pixel transfer with Ti:Saphire; e) one PIB polymer pixel transfer with Ti:Saphire,;f) multiple PEI polymer pixel transfer with XeCl excimer laser; g) multiple PECH polymer pixel transfer with XeCl excimer laser.

Preparatory tests for further simulants, interferents and warfare agents testing have been started on the resonators .SAW sensors have been tested using the Network Analyzer upon exposure to concentrations of different solvent vapours as: acetone. Response curves were obtained at 20° C.

* Training of young scientists

|

|

Name and Surname |

Location |

Period |

|

Young scientists from NPD group (Rome) |

Fabio Dipietranotonio |

Switzerland, PSI |

10-13 Nov. 2008 |

|

Bucharest, NILPRP |

6-9 April 2009 |

||

|

Domenico Cannata |

Switzerland, PSI |

10-13 Nov.2008 |

|

|

Bucharest, NILPRP |

6-9 April 2009 |

||

|

Young scientists from PPD group

(Bucharest) |

Valentina Carmen Dinca |

Switzerland, PSI |

4-26 May 2008 |

|

Switzerland, PSI |

7-22 Sept 2008 |

||

|

Switzerland, PSI |

2 -16 Nov. 2008 |

||

|

Switzerland, PSI |

15-25 June 2009 |

||

|

E-MRS, Strasbourg |

7-14 June 2009 |

||

|

George Epurescu |

Switzerland, PSI |

4-13 May 2008 |

|

|

Alexandra Palla-Papavlu |

Switzerland, PSI |

15-25 June 2009 |

|

|

Switzerland, PSI |

10 September - 10 December 2009 |

||

|

E-MRS Strasbourg |

7-14 June 2009 |

1. 8-10 August 2007, Villigen (Zurich), Switzerland : Kick off meeting

2. 22-26 January 2008, Rome, Italy

3. 1-3 October 2009, Bucharest, Romania

*Bilateral and/or occasional meetings

· Dr. Maria Dinescu, Dr. Thomas Lippert, (June 2008)

· Dr. Maria Dinescu and Dr. Thomas Lippert, (January 2009)

· Dr. Enrico Verona (IDAC-CNR), Dr. Thomas Lippert (PSI) and Dr. Valentina Carmen Dinca (NILPRP), (February 2009)

· Dr. Maria Dinescu, Dr. Thomas Lippert, (May 2009)

· Dr. Enrico Verona, Dr. Maria Dinescu, ( May 2009)

· Dr. Enrico Verona, Dr. Maria Dinescu, Dr. Thomas Lippert, September 2009

Visibility of the project:

Papers presented at International Conferences:

1. 6th International Conference of Photo-Excited Processes and Applications (ICPEPA 2008) Sapporo, Japan, 9-12 Sept. 2008, V.C. Dinca, A Palla-Papavlu, C. Constantinescu, N.D. Scarisoreanu, M. Filipescu, M. Dinescu “Laser printing of polymers structures” (Invited talk)

2. Advanced Laser Techologies (ALT 08), September 13-18, 2008, Siófok, Hungary, V.C. Dinca, A Palla-Papavlu, C. Constantinescu, N.D. Scarisoreanu, M. Filipescu, M. Dinescu, Anca Roseanu, Paula Florian, “Laser processing of organic compounds” (Invited talk)

3. E-MRS Strasbourg, 8-14 June 2009, (V. Dinca, R. Fardel, F. Di Pietrantonio, D. Cannatà, E. Verona, A. Palla-Papavlu, A. Matei, M. Dinescu and T.Lippert) , “Laser-Induced Forward Transfer: An Approach to Single-Step Polymer Microsensor Microfabrication ”(Oral presentation)

4. E-MRS Strasbourg, 8-14 June 2009, (A. Palla-Papavlu, C. Constantinescu, V. Dinca, A. Matei, A. Moldovan, A. Nedelcea, V. Ion, M. Dinescu) ”Polyisobutylene thin films obtained by Matrix Assisted Pulsed Laser Evaporation for sensors applications” (Oral presentation)

1. V. Dinca, R. Fardel, F. Di Pietrantonio, D. Cannatà, E. Verona, A. Palla-Papavlu, A. Matei, M. Dinescu and T.Lippert) , “Laser-Induced Forward Transfer: An Approach to Single-Step Polymer Microsensor Microfabrication ” (Sensors letter, in press)

2. A. Palla-Papavlu, C. Constantinescu, V. Dinca, A. Matei, A. Moldovan, A. Nedelcea, V. Ion, M. Dinescu) ”Polyisobutylene thin films obtained by Matrix Assisted Pulsed Laser Evaporation for sensors applications” (Sensors letter, in press)

Abstracts sent for presentation to

international conferences:

1.

"Polymer pixel

enhancement by laser induced forward transfer for sensor application”

(V. Dinca, A. Palla-Papavlu, A. Matei, M. Dinescu, J. Shaw-Stewart, R. Fardel,

T.

Tippert, F. Di Pietrantonio, D. Cannatà, M.

Benetti, E. Verona) (Accepted for presentation to COLA 2009, Singapore)

2.

“A comparative study

of DRL-LIFT and LIFT on integrated polyisobutilene polymer matrices”

(V. Dinca, A. Palla-Papavlu, A. Matei, M. Dinescu, J. Shaw-Stewart, T.

Tippert, F. Di

Pietrantonio, D. Cannatà, M. Benetti, E. Verona) (Accepted for presentation to

COLA 2009, Singapore)

* Contact

NPD

Enrico Verona, Dr.

Research Director, Laboratory Head

CNR – Istituto di Acustica “O.M. Corbino”, (IDAC – CNR)

Via del Fosso del Cavaliere, 100, I-00133 Roma, Italy

Telephone: +39 064 993 4481

+39 335 816 0409

Fax: +39 062 066 0061

e-mail: enrico.verona@idac.rm.cnr.it

PPD

Dinescu Maria, Prof. Dr.

Senior Scientist, Laboratory Head

NILPRP – National Institute for Lasers, Plasma and Radiation Physics (INFLPR)

Bd. Atomistilor 409, PO Box MG-16, RO 77125 Magurele, Bucharest

Telephone: +4 021 457 44 14

+4 021 457 44 67

Fax: +4 021 457 42 43

Project Participant

Thomas Lippert, Dr.

Senior lecturer

ETH Zurich and head of Materials Group, Paul Scherrer Institute,

5232 Villigen-PSI, Switzerland

Telephone: +41 56 310 40 76

Fax: +41 56 310 26 88

e-mail: thomas.lippert@psi.ch