Project name: Dust mobilization and collection by laser and plasma

Project code: C4-13

Project acronym: DUSTCO

Programme Name: IFA-CEA Partnership for Joint Research and Development Projects

Field: Fundamental Research on Energy

Topic: Nuclear Fusion and Fission

RO Project leader: Maria Dinescu

FR Project leader: Christian GRISOLIA

Project summary:

Energy is the single most important commodity that has been a key in the development of human society. In the present day there is virtually no field of human activity, from agriculture to information technology, which is not reliant on the use of energy. The future operation of the ITER reactor at Cadarache is a great commitment and a monumental undertaking meant to address efficient and responsible production of energy. The scale and complexity of this project are hard to express in simple words, and yet all the aspects that comprise it are critical to its success.

The successful mobilization, transport and collection of dust created as by-product during the operation of the tokamak reactor is an important piece of the puzzle, and we think that the framework of the IFA-CEA programme presents an excellent opportunity to achieve a significant progress, beyond the state-of-the-art, in tackling this issue. As such, we propose a complex, interdisciplinary approach that combines elements of pulsed laser particle mobilization, plasmas and electric fields assistance in order to explore mechanisms for the mobilization, transport and collection of dust/powders from various types of surfaces.

We will check if the laser irradiation, plasma jet sources, and laser beams coupled with an incident plasma source are viable methods to achieve particles mobilization and transport. These experiments will also be carried out in electric field to see if ionized particles can be ultimately collected.

While our effort will revolve mainly around the treatment of fusion energy powders, it can also yield relevant results concerning the removal of dust from sensitive surfaces, such as those used in micro-devices for energy storage and production. Specifics related to the proposed materials, techniques and analyses are detailed in the subsequent sections of this proposal.

The project's work plan has three stages spanning over a period of 24 months. It comprises four work packages that will focus on: i) Production of particles and surfaces with particles by lasers and plasmas (WP1), ii) Mobilization, transport, collection of particles from contaminated surfaces (WP2), iii) Analysis of collection efficiency, material characterization (WP3), and iv) Dissemination of results through scientific papers and conference participations (WP4).

The greatest contribution that this project will bring is an in-depth understanding of the mechanisms governing dust mobilization, transport and collection employing a variety of laser and/or plasma techniques. This is expected to have a significant impact on the successful operation of the ITER tokamak, which is a next-generation fusion energy reactor requiring a non-invasive approach to the removal and handling of the large quantities of tritiated dust expected to be produced throughout its operation. If no successful process is found, the operation of ITER could be constraint due to in vessel activities needed to recover these small particles by sucking under atmosphere.

Economically, the financial effort dedicated to funding such a project is very small when compared to the potential benefits stemming from finding a plausible approach to solve one of ITER's critical operability issues. The collective results of the project would impact not only the operability of the ITER facility, but they will also contribute to an environmentally friendly solution to the subsequent handling of these hazardous by-products. Changes brought about to their chemistry through nitrating or reducing of the powders by laser and plasma techniques also impact the issue of their subsequent disposal. It should be noted that laser and plasma techniques are clean themselves, and do not pose additional stress on the facility, from an environmental perspective.

First stage - December 2014

(stage value: 160,000 lei)

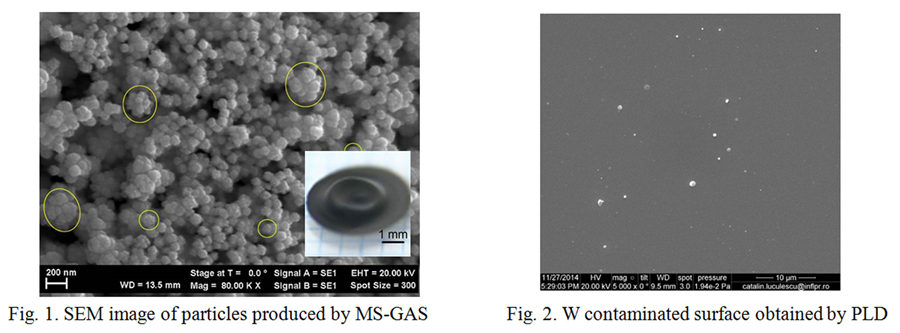

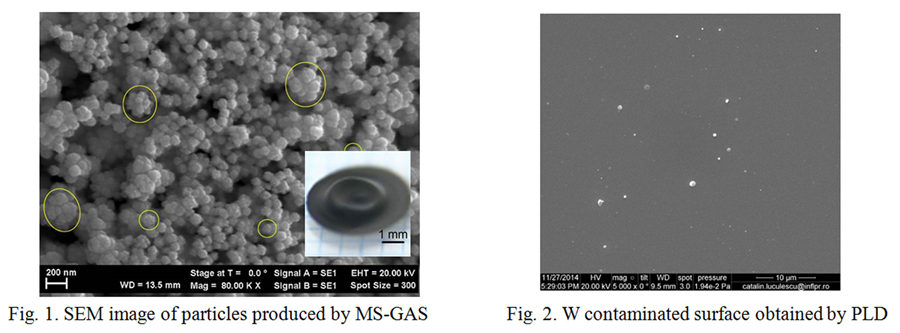

W particles having sizes between 70-100 nm have been synthesized using a cluster source that combines magnetron sputtering and condensation of metal vapours in inert gas - MS-GAS (Fig. 1). This proved to be a very efficient approach towards the production of high quantities of metal powders (see inset in Fig. 1) having a narrow size distribution. On the other hand, laser-based methods (pulsed laser deposition - PLD, ablation of a metal target in liquid medium) have yielded surfaces having a much lower particle density, which would be better suited for fundamental studies (Fig. 2).

Second stage - December 2015 (stage value: 200,000 lei)

Third stage - June 2016 (stage value: 85,000 lei)